FAQ

PES – polyester

NY – nylon

PU – polyurethane

PA – polyamide

AC – acrylic

PP – polypropylene

VI - viscose

CO – cotton

LI – linen

To increase the safety of products in everyday use, more and more manufacturers, including producers of fabrics, test them for the possible presence of toxic substances that may have been used in the manufacturing process. The certificate “TRUSTWORTHY TEXTILES” Öko-Tex Standard 100 is granted by the members of the International Association for Research and Testing in the Field of Textile and Leather Ecology Öko-Tex and confirms that the fabric is free from harmful substances, such as pesticides, chlorophenols, formaldehyde, allergising colouring, banned azo dyes and extractable heavy metals. The certificate is only awarded to those textiles whose all components have been tested at each production stage and obtained positive results. When applying for the certification, the manufacturer must be prepared for a thorough analysis of the production process,inspectors unexpectedly visiting the plant, and frequent checks of the products (once the Öko-Tex Standard 100 mark is already awarded).

You can, however, we only send such samplers to companies in the furniture business. For more information, please contact the Sales Representative for your region (the contact information is listed in the Contact page).

We put extra effort into making sure that all images on our website reflect the colour of the fabric as close to the original as possible. Still, what you see on your screen is affected by many things, such as the screen’s calibration, the web browser displaying the website, the room's lighting, etc. It is therefore possible that the colour displayed on the screen may differ slightly from the fabric's real colour.

The range of products within a collection presented on the website is always up to date.

Most fabrics are 140 cm (+/- 2 cm) wide or 142 cm (+/- 2 cm) wide. The width of the collection is always specified in the material safety data sheet.

Although we often say “material” and “fabric” interchangeably, this is incorrect. These words do not mean the same thing. Not every material is a fabric.

Material is a textile product made directly from fibres or in two stages, where the first one is making yarn from the fibres, followed by making other textile products from the yarn. Materials are divided into knit and woven fabrics. They differ in how their threads are woven which also determines their application and functional properties.

Knit fabric is a flat textile product always made from two sets of yarn: warp yarn and weft yarn. The warp yarn goes along the fabric (vertical thread), while the weft yarn is perpendicular (horizontal thread). Most often, knit fabrics are used for making bed linen, clothing and furniture upholstery. Knit fabrics are highly resistant to damage and deformation.

Woven fabric is a textile product made from one or more yarns, interwoven to create loops. Woven fabric is most often used for making sweaters, scarves, gloves or tights. Woven fabric is elastic, stretchable in all directions, soft and breathable.

The most popular types of upholstery knit fabric are:

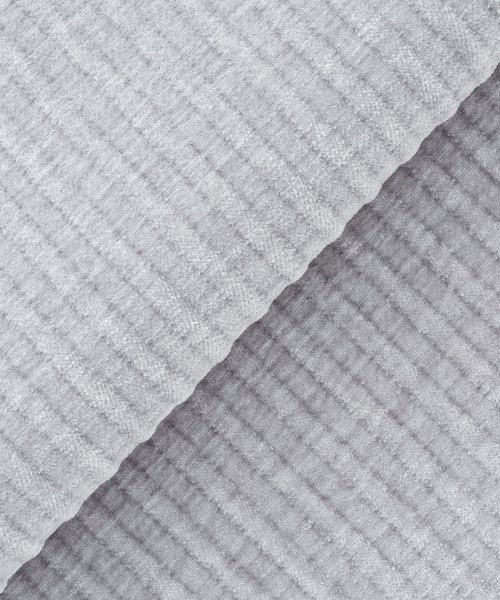

Plaited fabric - flat knit fabric, made by intermeshing, at a straight angle, of two sets of yarn: the warp yarn (vertical thread) and weft yarn (horizontal thread).

The warp and weft yarn are interwoven following a specific weave pattern.

Examples: Look (Agmamito), Puento (Toccare), Samoa (Agmamito), Urban (Toccare).

Plush - fabric with nap (pile) coat, made by cutting the threads of the additional nap warp yarn or the additional nap weft yarn, followed by defibring the remaining ends. Depending on the method of production, plush is divided into:

Velour (warp yarn plush) - a plush fabric where the nap coat is made from the warp yarn;

Velveteen (weft yarn plush) - a plush fabric where the nap coat is made from the weft yarn;

Velvet - plush with very short nap, under 3 mm. The pile coat is made by introducing additional nap yarns in the form of loops, placed between the warp and weft yarns. The additional may remain uncut (looped velvet) or may be cut (sheared velvet).

Examples: Cortina (Tocacre), Salvador (Agmamito), Tarim (Agmamito), Torre (Toccare).

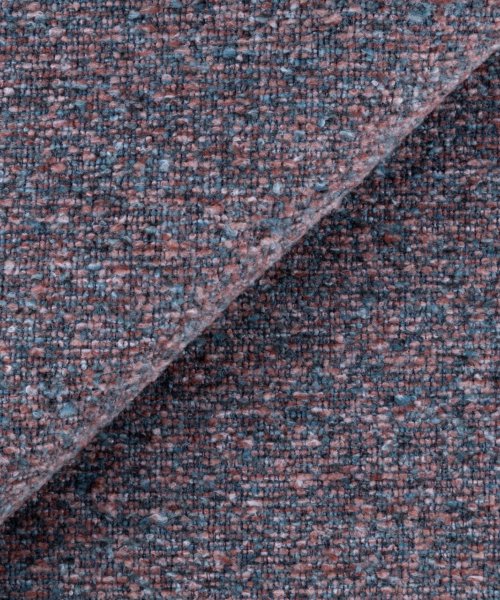

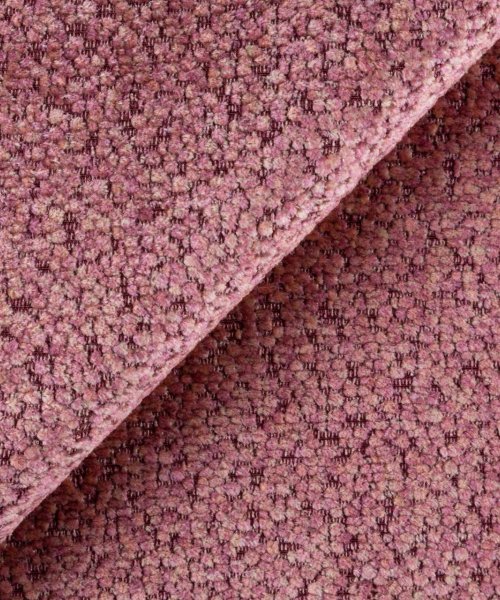

Chenille - knit fabric with chenille yarn in the warp and/or weft yarn. Chenille yarn is made from two interwoven yarns, with short lengths of yarn placed in between, resulting in short pile. The chenille yarn makes the fabric's surface irregular and slightly shiny. Chenille is one of the softest fabrics to touch, yet also one of the most durable upholstery options. Depending on the used yarn, chenille may be fluffy (plush-like) or relatively smooth.

Examples: Alta (Agmamito), Concept (Toccare), Lucca (Toccare), Presto (Toccare).

Flock - a textile product made by depositing, electrostatically, decorative textile clips onto a knit fabric covered with adhesive. The clips, or the flock, is made from fibres (predominantly nylon or polyester fibres) of certain length (0.25 mm to 5 mm). Flock fabrics are exceptionally soft and pleasant to touch, yet amazingly strong.

Examples: Sarenza (Toccare), Verso (Tocacre).

Eco-leather / artificial leather - a material imitating natural leather. A polyester fabric coated with a layer of plastic, whose face is embossed with a pattern that makes it look similar to natural leather.

Synthetic leather does not absorb water, which makes it easier to keep clean, but on the other hand it does not permeate air and that affects the comfort of use of the furniture.

Examples: Eco-Soft (Agmamito), Giovanni (Agmamito), Satin (Agmamito), Sorrento (Toccare).

Nubuck - a synthetic variety of suede, but with all its natural benefits. Extremely durable and resistant to abrasion.

Examples: Esperta (Tocacre), Mindelo (Agmamito), Santorini (Toccare), Zaria (Agmamito)

NATURAL FIBRES:

WOOL (WO/LW)

High quality wool is flexible and durable, lasts long without any signs of use and is protected by a natural lanolin coat. Still, when improperly maintained it can felt, making it infrequently used for furniture production.

COTTON (CO)

Thanks to the modern production processes, natural cotton fibres are successfully used for making top quality upholstery fabrics. Cotton upholstered furniture is superbly comfortable - the fabric is unusually soft and gentle to touch, ecologically safe, absorbs moisture well and allows human skin to breath. Moreover, cotton fibres are very strong and durable.

LINEN (LI)

Linen is very resistant to tearing and rubbing. Linen is very pleasant in contact with skin as it absorbs moisture and lets the skin breathe. The disadvantage is the relatively low fibre flexibility, resulting in an easily wrinkled material.

Did you know that ...? The functional properties of natural fibres can be improved with adequate processing or combining them with synthetic fibres to produce a stronger and more flexible product. A good example of this approach is PUENTO, by Toccare - the fabric's durability was improved with polyester fibres (the fabric contains 15% polyester and 85% cotton).

GENUINE LEATHER

Gentle and unique structure, optimal hygienic properties (breathable, absorbs moisture, adapts to ambient temperature) and sensationally soft and gentle. Unfortunately, susceptible to dirt, dyes and cracking.

SYNTHETIC FIBRES:

POLYESTER (PES)

The list of advantages is impressively lengthy - very durable, flexible (no kinks), resistant to wrinkling, relatively low water absorption and, as a result, easy to keep clean.

POLYPROPYLENE (PP)

High air permeability and relatively low steam permeability. One of the most chemically resistant materials to all sorts of compounds.

POLYURETHANE (PU)

Its elastic fibres are easily deformable and regain their original dimensions. The most often used material for making synthetic leather.

POLYAMIDE (PA)

Excellent resistance to abrasion, wear or tearing. Slightly less elastic than polyester and more prone to wrinkling. Polyamide is sensitive to sun rays - fades or yellows when exposed to long-term operation of natural or artificial light.

NYLON (NY)

Nylon is highly durable, tensile and lightweight, dries quickly and is resistant to wrinkling. Evacuates moisture very quickly and the fabric's properties prevent the growth of fungi and bacteria on its surface.

ACRYLIC (AC)

The most common, cheaper and synthetic alternative to wool. The fibres are very flexible, easy to clean and resistant to sun rays. Still, the disadvantages are plenty: low rubbing resistance, high susceptibility to pilling, high flammability. Additionally, acrylic fibres are not hygroscopic (moisture is not absorbed).

The newest production technologies lead to massive improvements in synthetic fibres and the development of preparations that eliminate, to a large extent, their negative properties. Consequently, there is no doubt that synthetic fibres can now compete with natural ones. Upholstery fabrics are often combinations of various types of fibres, with the fabric’s properties decided by their proportions.

Advantages of synthetic fibres:

- high tensile resistance

- high elasticity - synthetic fibres are wrinkle-resistant

- quick drying

- high resistance to sun rays (mostly applies to polyester fibres)

- high resistance to fungi and bacteria

- hypo-allergenic - synthetic fibres do not cause allergies, but due to their electrostatic properties they attract dust and are not recommended for people suffering from allergies

MARTINDALE RUB TEST

The Martindale rub test is the most common method of testing the fabric’s resistant to abrasion. The test shows how long the fabric will stay flawless and bear no signs of daily use. During the test, a special machine is rubbing the examined fabric with wool or abrasive paper and with serious pressure. The test continues until visible changes in the fabric's structure are spotted. In practice, that means that the higher the number of cycles the fabric sustained, the longer normal signs of use will not be visible. Right, OK, but how does that translate into everyday life? It is assumed that for an intensively used piece of furniture 4,000 cycles is equivalent to 1 year.

TENSILE STRENGTH

The test examines the fabric’s resistance to the applied force. In other words, it shows how much the fabric can be tensioned before it tears.

The tested piece of fabric is placed between two devices. Under force, the fabric's yarns are stretched, until they break.

The test results are shown separately for warp yarns and weft yarns. A score of over 600 N falls into the highest category (A).

TEAR STRENGTH

Resistance to tearing - a piece of fabric, with a pre-torn or damaged line in the middle, is placed between two holding clips. The parameters of the force needed to tear the material are the parameters determining the value of the given examination

The test results are shown separately for warp yarns and weft yarns. A score equal to or over 40 N falls into the highest category (A).

SLIPPAGE OF YARNS IN SEAMS

This test aims to verify the maximal relocation of seams in the daily use of the fabric.

For the examination, two pieces of fabric, sewn together, are placed between two testing devices. The seam's strength is examined by exerting force on the fabric. The constant force elongates the yarns. This elongation is then measured, in millimetres.

The test results are shown separately for warp yarns and weft yarns. A score equal to or lower than 4 mm falls into the highest category (A).

MARTINDALE RUB TEST (resistance to abrasion)

The test examines the fabric's resistance to abrasion and its result indicates how long a given fabric will resist rubbing in daily use.

The tested fabric is placed between two discs made from fabric (less frequently from abrasive paper) that rub against the tested piece at constant force.

The tested fabric is subjected to circular rubbing.

The abrasion resistance is indicated in cycles - the higher the count, the more resistant the fabric is. Depending on the type of fabric, the highest category (A) covers fabrics whose score is equal or higher than 35,000 or 45,000 cycles.

It is assumed that 2,000 cycles are equivalent to 1 year of use.

PILLING PROPENSITY

Pilling is the process of creation of small balls (pills) on the fabric's surface. They are formed by intertwined and knotted strands of fabric. Synthetic fibres, especially made from polyester, are prone to pilling.

Pilling propensity is specified on a scale from 1 to 5, where 5 is the maximal resistance to pilling.

RESISTANCE TO DISCOLOURATION DUE TO LIGHT

A special chamber, in which the tested fabric is subjected to adequately strong light, is used for testing its resistance to discolouration due to light. Upon completion of the test, the fabric is compared against a piece that has not been tested. The level of discolouration determines the fabric's propensity to discolouration under artificial light.

A scale from 1 to 8 is used, where 8 means exceptional resistance of the fabric to fading under artificial light.

Fabrics whose resistance to discolouration due to light is 6 or higher can be used outdoors. A score of 5 is considered the highest score in the category of upholstery fabrics used indoors.

RESISTANCE OF COLOUR TO RUBBING (DRY / WET)

The fabric is tested in two devices, one for dry rubbing, the other one for wet rubbing. Upon the completion of the test, the change of the fabric's colour is examined. The fabric's colour and its propensity to fade after rubbing is evaluated.

The results are presented on a scale from 1 to 5. A score equal to or higher than 4 falls into the highest category (A).

FLAMMABILITY TEST

Modern fabrics may undergo the process of flame retardation, which is especially important for materials to be used in HoReCa.

There are two types of tests examining the flammability of upholstery fabrics: subjecting the fabric to a smouldering cigarette or a flame from a gas burner, whose thermal power is equal to that of a lit match. The test duration is 15 seconds in both cases.

The fabric is considered flame retardant if, during the test, the cigarette fails to burn out in its entirety, there is no flame or progressing smouldering or, if the source of ignition is the gas, the flame disappears upon removal of the burner (or within 2 seconds after the burner is removed) or there is no progressive smouldering.

COMPLIANCE WITH THE REACH REGULATION / OEKO TEX

To increase the safety of products in everyday use, more and more manufacturers, including producers of fabrics, test them for the possible presence of toxic substances that may have been used in the manufacturing process. The fabric is completely safe for use and environmentally friendly if it contains no harmful chemical substances listed in the REACH regulation. The certificate “TRUSTWORTHY TEXTILES” Öko-Tex Standard 100 is another way of ensuring the safety of fabrics. The label is granted by the members of the International Association for Research and Testing in the Field of Textile and Leather Ecology Öko-Tex and confirms that the fabric is free from harmful substances, such as pesticides, chlorophenols, formaldehyde, allergising colouring, banned azo dyes and extractable heavy metals. The certificate is only awarded to those textiles whose all components have been tested at each production stage and obtained positive results. When applying for the certification, the manufacturer must be prepared for a thorough analysis of the production process,inspectors unexpectedly visiting the plant, and frequent checks of the products (once the Öko-Tex Standard 100 mark is already awarded). The certificate is issued for 12 months, which may be extended by an additional year.